In competitive karting, where races are often won or lost by fractions of a second, having a professionally blueprinted engine isn’t just a luxury—it’s a necessity. If you’re serious about fighting for the podium, every mechanical detail matters, and your engine is the heart of your performance.

What Is Engine Blueprinting?

Blueprinting is the meticulous process of disassembling, inspecting, measuring, and reassembling an engine to optimize its performance within class-legal tolerances. It ensures that every component is working together in perfect harmony—balanced, matched, and fine-tuned to the highest standard allowed by the rulebook.

Why It Matters

- Consistency and Reliability: Blueprinting enhances engine reliability and consistency across heats and race weekends. The last thing you want when leading a race is an engine failure due to overlooked mechanical imbalance or stress.

- Maximum Legal Performance: Even when all engines are “stock,” there’s still a lot of performance left on the table. Blueprinting extracts every bit of legal horsepower by optimizing clearances, alignments, and timing.

- Podium Potential: When you’re chasing a national championship or running in a top-tier program, a blueprinted engine could be the edge that separates first from fifth.

The Blueprinting Process: Step-by-Step

- Initial Inspection: The engine is completely disassembled and inspected. This includes checking for wear, cracks, and manufacturing inconsistencies.

- Precision Measurement: Every part—cylinder, piston, crankshaft, bearings, reed block, carburetor, etc.—is measured to exact tolerances using micrometers, dial indicators, and other specialized tools.

- Component Matching & Balancing: Parts are matched and balanced for optimal performance. This may include port timing adjustments, squish band setting, piston-to-wall clearance optimization, and crankshaft truing.

- Reassembly: The engine is reassembled with precision, using high-quality lubricants, seals, and fasteners—torqued to exact specs.

- Sealing/Tagging: If part of a sanctioned series, the engine may be sealed to meet national technical regulations.

Why It Costs More

Blueprinting isn’t a bolt-on mod. It requires:

- Specialized tools and equipment

- Years of experience and knowledge of how engines behave under racing stress

- Hours of hands-on labor and quality control

- Custom measuring, shimming, grinding, and sometimes replacing out-of-spec parts

You’re not just buying parts—you’re investing in a handcrafted powerplant built for winning.

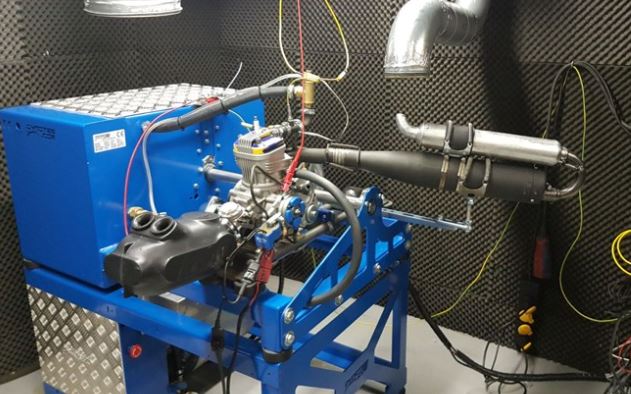

The Role of Dyno Testing & Break-In

After blueprinting, your engine should be dyno-tested to validate power output and ensure it’s running clean across the RPM range. The break-in process is also essential—it seats the piston rings, stabilizes temperatures, and ensures all parts wear together smoothly. Skipping this can reduce longevity and compromise all the work put into the blueprint.

In summary, blueprinting is about maximizing performance, reliability, and legality. For any serious karter aiming for national-level results, a blueprinted engine isn’t optional—it’s foundational.